Dry Wall Easy to Remove Wall Mount Tape Two Lbs

How to Hang Drywall Like a Pro

Get that sheetrock up fast

Introduction

Installing drywall is not rocket science, but it will go faster and look better if you learn the fundamentals before you start (instead of after you're done).

Tools Required

Materials Required

- 1-1/4-in. drywall screws

- 1-5/8-in. drywall screws

- 2 x 2 (for optional crutch)

- Drywall

- Drywall nails

Drywall is one of the easiest-to-use and cheapest construction materials in the world. Even a serious mistake will make you chuckle, knowing you've wasted little time and probably less than five bucks. And the money you save handling the task yourself will come in handy when furnishing that new room.

Hanging "rock" (short for "sheetrock") doesn't require a lot of finesse, but it is heavy work. But if you are in reasonably good physical condition, don't be afraid to tackle one, two or even three rooms on your own. It's sometimes hard to interest a pro in hanging just a room or two, or even get on the schedule. Besides, defining and covering the walls with a finished material can be satisfying.

This how to install drywall article will demonstrate the basics of hanging drywall. If you do a good job of hanging drywall, the drywall can be taped and finished smoothly and easily. "Taping" refers to the process of filling fastener holes, applying joint tape and three layers of taping compound to seams and corners, and then sanding. (Read more about drywall taping here.) Poor drywall hanging techniques make it difficult for even a seasoned taper to deliver a flat, uncracked surface that's free of nail pops and ready for paint. We'll show you the techniques and tools the pros use to get the drywall job done fast and in a way that makes taping as painless as possible.

Video: How to Tape and Mud Drywall

Project step-by-step (15)

Step 1

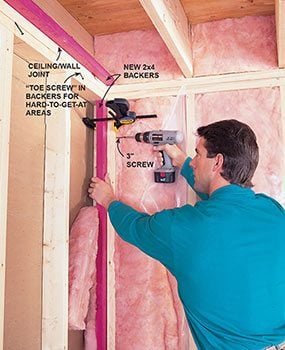

Fasten Backers at Corners

- Fasten wood backing wherever drywall ends have no support within 4 inches.

- Note: Make sure to check corners and ceiling/wall joints.

Step 2

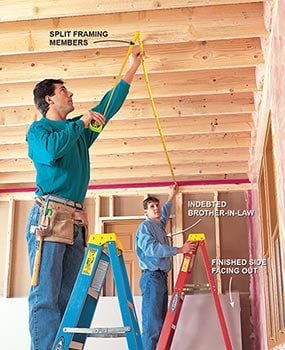

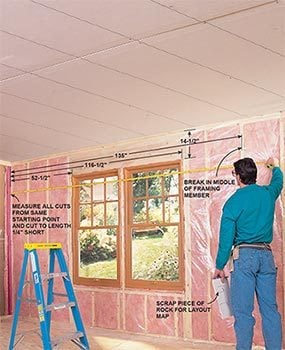

Measure Carefully

- Measure from the end of the ceiling to the middle of a joist and cut the sheet to length.

- Pro tip: End cuts should split framing members. Gaps at ends and splices should be less than 1/4 inch.

- Mark fastening guidelines every 16 inches from the end of the sheet with a drywall square.

- Cut overall lengths 1/4 inch shorter for easier fitting.

Selecting Drywall

Most drywalling calls for three basic types and thicknesses of material:

- Half-inch for framing spans of 16 inches or less.

- Five-eighths-inch for spans up to 24 inches on ceilings. The 5/8-inch drywall is also called Type X or fire-resistant. It is used in areas where a firewall is required, such as between a house and an attached garage. Consult your local building official for installation specifics.

- Half-inch drywall that's water-resistant for humid areas such as baths (humid, not wet). This material is not acceptable for ceilings or areas such as tiled shower enclosures. Mold-resistant drywall is also sold for areas like basements where mold might be a concern.

Door and window jambs and electrical outlets are usually set up for 1/2-inch drywall, so check to confirm. Three-eighths-inch and 1/4-inch are available as well but are rarely used except on curved wall surfaces or areas where thinner rock is required. For example, if you're patching old plaster walls, 3/8-inch may be the only thickness that will match the depth of the plaster.

Drywall usually comes in either 4x8 or 4x12 sizes. If you live in an area large enough to support a commercial supplier, it'll offer more variety than an average lumberyard. It may have 9-, 10- and 14-foot lengths, 54-inch widths for 9-foot. ceilings and odd things like flexible drywall for curved surfaces. Drywall lengths don't radically affect overall material cost. If you think you can handle 12-foot. sheets (and if they'll fit through the stairwells), they're the way to go. You'll have far less waste and fewer seams to tape. Keep in mind that a 4x8 sheet weighs 55 lbs. and a 12-footer about 82 lbs.

Step 3

Score the Drywall

- Measure the length needed and score the paper face with a utility knife, using a drywall square as a straightedge.

Step 4

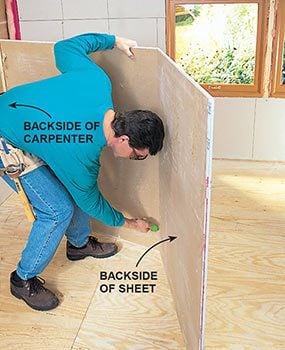

Snap the Drywall

- Snap the sheet, fold it open and cut through the paper on the backside.

Step 5

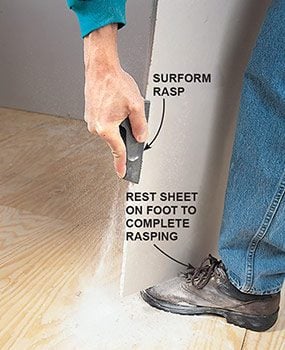

Smooth the Edges

- Smooth rough edges on cut ends with a Surform tool to ensure tight joints.

Using a Drywall Lift

Drywall is heavy stuff, so consider saving your back by renting a drywall lift for a day. A lift is fantastic if you're shorthanded or installing 12-foot sheets. It disassembles easily, weighs about 75 lbs. and will fit in a minivan or small pickup. A lift makes it possible to hang rock solo, but it's still nice to have a helper for loading the rock onto the lift. A lift tilts from vertical to horizontal. Wheels allow you to roll it up to the drywall stack, load a sheet onto the rack, roll it back into position and crank the sheet up into place. Although a lift can also be used for wall placement, its strong suit is ceilings.

Step 6

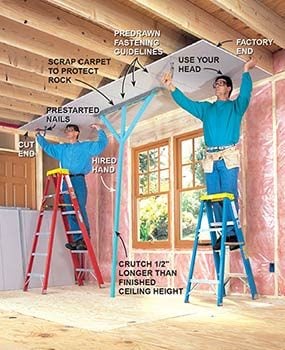

Tack the Sheet in Place

- Hoist the ceiling sheets overhead and tack them into place using a "crutch" made of 2x2s to support the lion's share of the weight.

- Prenail and position the sheet, tacking it to the joists.

Step 7

Measure the Upper Sheet

- Measure the distance from a wall corner to the center of a framing member, also recording distances for cutouts and door and window openings.

- Pro tip: Avoid placing joints over doors and window corners, where they may crack.

Step 8

Cut the Openings

- Cut window and door notches from a single sheet by sawing sides with a drywall saw.

- Pro tip: A keyhole saw is slower, but it is an acceptable substitute for long cuts.

Step 9

Finish the Cut

- Score the third side of the notch with a utility knife.

- Snap the section loose and complete the cut from the backside.

- Pro tip: For quick rip cuts, drag your utility knife behind the T-square as you slide it along the top (nestle the blade of the knife against the ruler part of the square).

Step 10

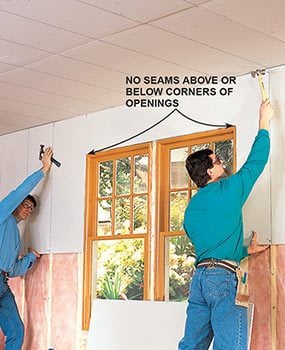

Hang the Top Sheet of Drywall

- Lift the top wall sheet, holding it tight against the ceiling, and tack it into place with nails.

- Pro tip: This sheet should be pushed tight against the ceiling before fastening. Never break joints at the edge of a window or door. These seams will eventually crack, and the buildup of taping materials will make installing casing difficult.

- Pro tip: Don't forget to mark fastener guidelines before lifting.

Step 11

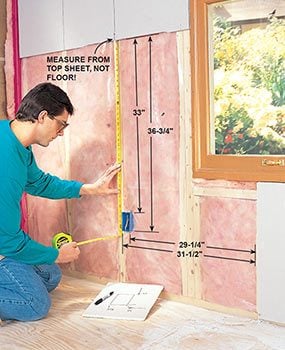

Measure Cutouts

- Measure electrical box cutouts from all four sides.

- Check all layout measurements twice before cutting!

Step 12

Mark and Cut the Drywall

- Transfer measurements to the drywall.

- Cut the outlet box openings with a keyhole saw.

- Pro tip: Take special care in planning and sawing cutouts for electrical boxes because if you miss, that oversized outlet hole is a bear to fix. Fixing a poorly cut or overcut hole is tricky, and the repair will never look quite right.

Spiral Cutout Saw

Although we don't show one in use here, pros now use spiral saws to cut openings for outlets, lights and even doors and windows. The basic idea is easy: Just mark the approximate center of the outlet or light, hang the sheet of drywall, and then poke the thin spiral bit through the center mark and follow the edge of the fixture all the way around. For door and window openings, hang the sheet across the opening and then follow the framing with the spiral bit—no measuring required, and you get a perfect cut every time. Of course, it takes a little practice to get the hang of the tool, it kicks up a lot of dust, and the basic tool costs $70 to $100, but if you're doing more than one room it may be worth the investment. For more information, see How to Use a Spiral Saw on Drywall

Step 13

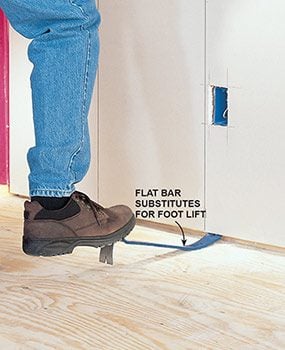

Lever Bottom Drywall Sheet into Place

- Hoist the bottom sheet with a foot lift or flat bar and tack it into place.

- If an opening needs small adjustments, shave the edges with your utility knife.

Step 14

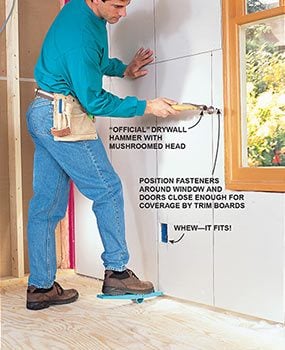

Finish Fastening with Screws

- Screw ceiling and walls with a screw gun.

- Pro tip: Use five fasteners per framing member, one in each tapered edge and three more spaced evenly every 12 inches. Slightly angle screws on the ends of sheets, where there is only 3/4 inch of wood left to catch screws. If you run them in too close to the end, the drywall core will break and they won't hold well.

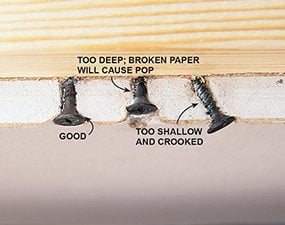

- Set screws and nails slightly below the surface of the paper, being careful not to break through into the gypsum core.

- To hide the fasteners, position them close to openings around windows and doors so the trim will cover them.

- Pro tip: Use 1-1/4 inch fasteners for 1/2-inch rock and 1-5/8 inch fasteners for 5/8-inch rock. Longer screws and nails are more prone to nail pops. Use as few nails as possible and only to tack up the sheets until you can get the screws in.

Step 15

Check for Protruding Screws

- After installing all the drywall, drag a putty knife over every single fastener.

- Note: If you hear a click, you've found a rogue fastener that needs to be set. Do not use your hammer to set a protruding screwhead — this may break the screw, creating a bigger hole to patch, and will cause a nail pop in the future.

- When you find a protruding screwhead, screw it in a little more with a screwdriver or a cordless drill.

- Remove any fasteners that missed the framing member.

More Drywall Hanging Tips From the Pros

- Don't try to save a couple of bucks by using scraps of drywall when you should be using a full sheet. The time and effort spent taping extra joints is rarely worth the money saved.

- Always join tapered edges to tapered edges.

- Stagger seams with each row of rock.

- Think ahead to make taping as easy as possible. Remove broken corners and loose chunks of rock, and cut out any blisters. These will all be filled in later with a fast-setting joint compound.

- Never use tapered edges for outside corners where corner bead goes. The thinner edge of the drywall makes it hard to properly fill the beaded edge with taping compound.

- As your last task, run a putty knife over all screwheads and set all fasteners below the surface. Since you put them in, it's your job (not the taper's) to make sure they're properly set. Tapers get very upset when they have to spend half of their first day on the job repairing improperly set fasteners. And the taper might be you.

Originally Published: November 03, 2020

Source: https://www.familyhandyman.com/project/how-to-hang-drywall-like-a-pro/

0 Response to "Dry Wall Easy to Remove Wall Mount Tape Two Lbs"

Postar um comentário